Originally published by FurnitureToday

Written By: Powell Slaughter | Senior Editor PSlaughter@furnituretoday.com

COLFAX, N.C. — Third-party certification of offshore mills producing composite wood products for compliance with EPA/CARB formaldehyde rules has problems.

That’s the word from Travis Snapp, founder and president of global certification and inspection agency as well as testing lab operator Benchmark International, for attendees at the recent AHFA Formaldehyde Workshop here.

“We have TPCs that should be kicked out of the program,” Snapp said. “There are still weaknesses, we still have holes, and we still have problem TPCs. … We don’t want any of our clients dragged into regulatory prosecutions.”

There’s a distinction between testing laboratories, which analyze products against published standards that give mostly straightforward instructions on how to carry out the analysis, vs. TPCs. “Being a TPC agency is a different animal from a testing lab,” Snapp said. “You need the knowledge of manufacturing to go in and see if they’re doing the right things for certification.”

For its part, Benchmark invested to place its own offices, labs and employees overseas. Right now it has 42 CARB TPCs and testing labs in 17 countries certifying 1,212 mills.

TPC competence

Snapp said a competent EPA/CARB TPC needs expertise in five areas: product certification, laboratory procedure and analysis, inspection of specific manufacturing processes, data management and, for international TPCs, foreign operations.

In terms of product certification, a TPC should operate under a well-documented and well-implemented quality management system with a high level of technical and ethical standards; ensure competent testing, inspection and surveillance to support all certified products; and maintain full compliance with ISO/IEC Standard 17065 and, when applicable, sector-specific requirements to meet market and regulatory needs.

Snapp believes a good TPC should be an expert in laboratory procedures and analysis. “If you don’t have capability in the lab, how can you go into a plant and make sure they’re doing it right? A simple question to ask is, ‘Does a TPC have a lab?’” he said.

Follow that with: What methods are listed in their scope, and are you free to visit the TPC’s facility? The latter is particularly important for importers. Onsite inspection can reveal problems: If there’s dust on the desiccator, for example, “it’s a good sign they’re not using the desiccator, Also, ask how they’ve performed in proficiency testing,” Snapp said, adding that’s important because TPCs can subcontract testing.

“I have a huge problem with subcontracting out for inspecting and testing … subcontracting as a backup is one thing, but if it’s your primary method there’s a problem,” Snapp said. “You have to demonstrate proficiency and knowledge in what you’re doing. Certification is not easy if you’re doing it right.”

In addition to knowledge of manufacturing processes, Snapp emphasized the importance of a TPC’s data management capability. Reporting requirements for EPA’s central data exchange includes a “mountain of information” such as mill physical, product and quality control information; correlation data and compliance testing for each batch or lot; failure notifications and annual reporting.

“And it all has to be in English,” Snapp added. “How is your (offshore) TPC going to handle the language barrier?”

What does it all mean?

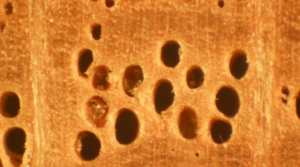

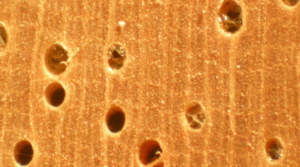

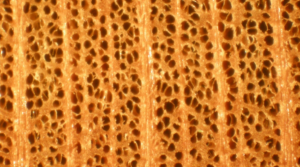

Snapp closed his presentation with photos of glue spreaders and mixing stations from what he said are current CARB-certified mills depicting abysmal production conditions.

“I’ve walked through some of these plants, and it burned the hairs in my nose – I didn’t need to bring my trimmers on the trip,” he quipped.

The bottom line for importers is that the new formaldehyde rule encompasses different facets of manufacturing, conversion, shipment and sales.

“The (offshore certification) program is still weak, and you must get involved with your TPCs to make sure the job is done right,” Snapp said.

http://www.furnituretoday.com/article/539866-third-party-certification-has-its-problems-offshore-companies/